Hard Abrasives

Ideal for low cost abrasive blast cleaning. Common applications include preparing surfaces for bonding, removing heat treat scale, deburring and general cleaning.

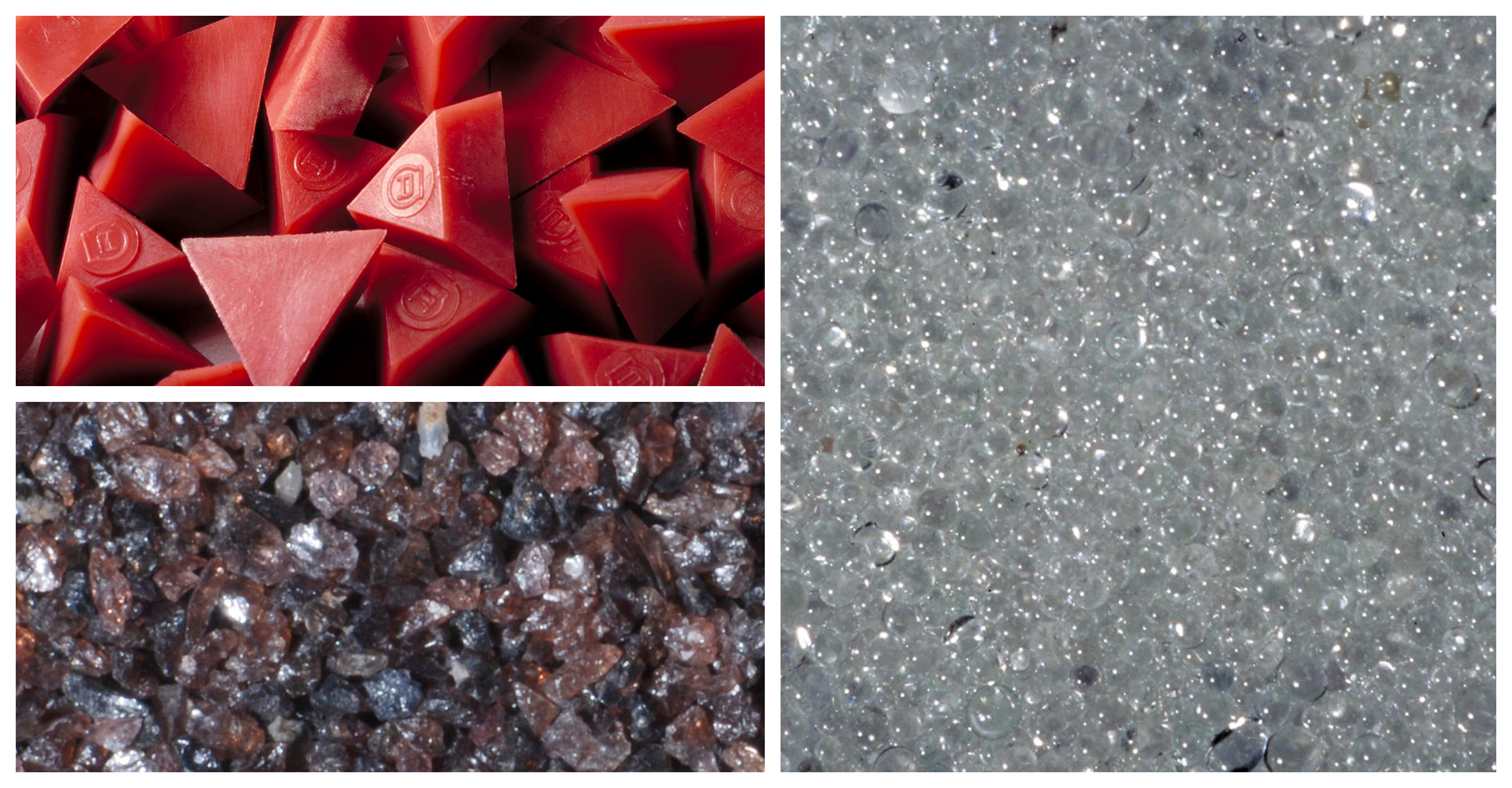

Aluminum Oxide (AO)

Producing an anchor pattern on surfaces for good recoating and bonding characteristics

Removing heavy foreign matter such as rust and mill-scale

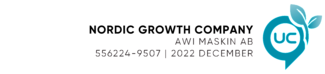

Glass Bead (GB)

Low cost cleaning, peening and deburring

Provides a matte finish

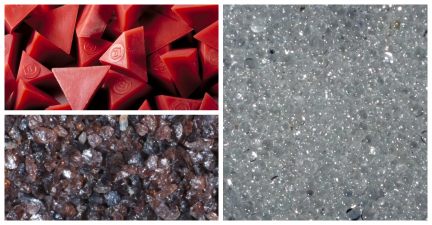

Tumbling Media

Nylon tumbling media is non-abrasive and very durable. This type of media is mixed with rubber parts in a cryogenic tumbler in order to aid in the deflashing of parts and reduce deflashing cycle times.

NT-1

Deflashing rubber parts in a cryogenic tumbler and in an ambient tumbler

Deflashing OD areas and some ID’s